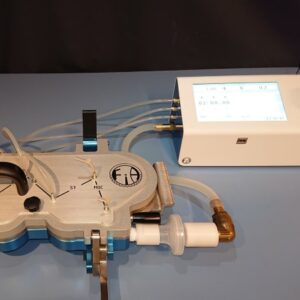

Nasal Spray Actuator

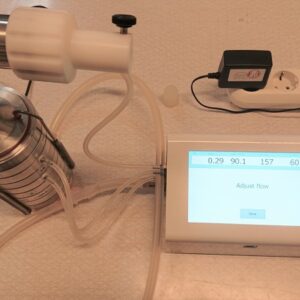

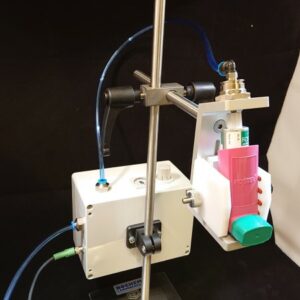

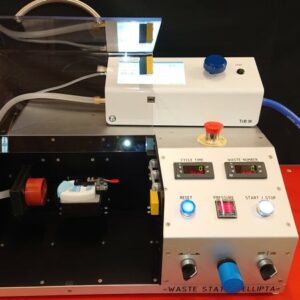

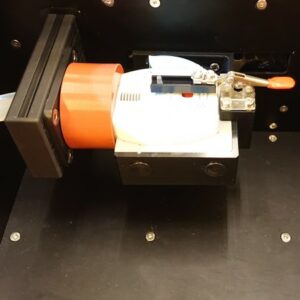

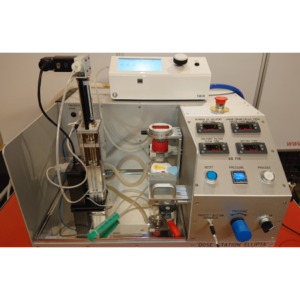

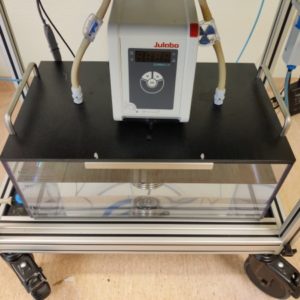

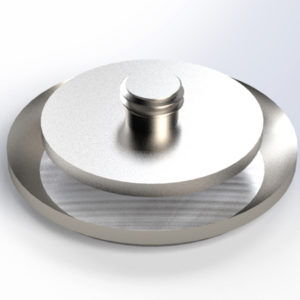

Take the worries out of Nasal Spray testing with FIA’s configurable NASAL SPRAY ACTUATOR. This actuation system enables the user to define multiple actuation methods. The nasal actuator measures the stroke travel distance and the force constantly, most notably end force at actuation. The velocity can be calculated from the distance and the time, recorded by the software.

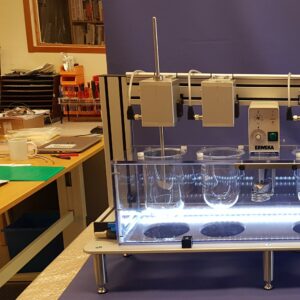

The nasal actuator control box can be used to set number of actuations for dosing, rest time between each actuation, number of waste dose etc. The equipment can be easily adapted to most device geometries. The compact and open design makes it perfect to integrate with dose collection on filter, and with optical techniques for determination of, e.g., spray pattern, plume geometry (laser pulsed camera) and droplet size (laser diffraction). We can guide you to the best possible solution based on our historic implementations.

Main benefits:

- Control pivotal parameters affecting the dose and the spray

- Release technical staff from routine functions and potential ergonomic strain

- Elucidate and record actuations in documented fashion

The regulatory guidelines which are applicable:

- US (FDA) – Guidance for Industry: Bioavailability and Bioequivalence for Nasal Aerosols and Nasal Sprays for Local Action, Draft 2003.

- US (FDA) – Nasal Spray and Inhalation Solution, Suspension, and Spray Drug Products CMC Guidance, Draft 2002.

- EU (EMEA) – Guideline on the Pharmaceutical Quality of Inhalation and Nasal Products, EMEA 2006.