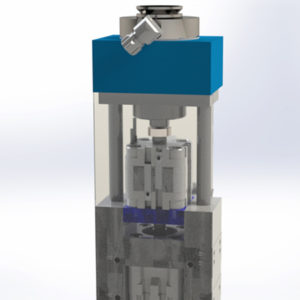

The standard FIA Chewing Apparatus DRT has a fixed operation for the masticating jaw´s movements. The linear movements Press and Open are achieved by a pneumatic cylinder that is forced to reach the end positions of the cylinder. In a similar way the twist motion must always reach the end position (Twist). (The positions of the twist cylinder are Twist and Regain, where only Twist is acting on the chewing gum by torque forces). The PTM module enables the ability to register pressure and torque forces during the mastication of chewing gums. There is also the possibility to set a maximum pressure value before the chewing sequence proceed with the twist movement. A PTM module can optionally be added to the apparatus which enable both pressure control with monitoring and torque monitoring. If the maximum value is reached for the pressure on the gum, the twisting movement of the jaws is achieved even if the end position of the Press-movement is not reached. With a hard gum, the gap between the jaws must not necessarily be reached before Twist motion is applied on the gum. The PTM module must be ordered for various amount of chewing cells during purchase of a new Chewing Apparatus. It can’t be retrofitted.

-

The Controlled Pump is designed to run 32 different pump programs that are easy selectable by two thumb wheels on the front panel. A program consists of one infusion motion and one withdrawal motion which are both configurable with stroke length and speed.

Start a selected pump program by press of the green “START/STOP” push button at the front panel. The pump will start infuse with parameters from the selected pump program. When the pump reach the programmed end position, it will immediately withdraw and then infuse and so on, as long as the latched push button is in its inner position.

Specifications

Dimensions: 122 x 140 x 350 mm. (WxDxH)

Weight: 4,4 kg.

Power supply: External power supply, 24 VDC 2,5 A

Glass syringe connection for external equipment: Luer Lock

Maximum infusion/withdrawal volume: 20 ml.

Maximum infusion/withdrawal rate (measured directly against atmosphere) 50 ml/s.

Lowest infusion/withdrawal rate (measured directly against atmosphere) 6 ml/s. -

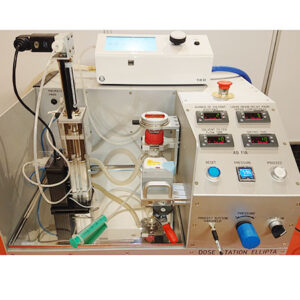

Dose Station Ellipta ®

This is our dedicated delivered dose uniformity test station for Ellipta ®, using the brilliant impinger filter dose collector. The latter is washable in-situ and can be ready for the next dose as part of the wet chemistry work-up procedure. The user works with the equipment in a fixed process which starts by the user placing the device in a nest which mates with the dose collector inlet. Thereafter aided by the station with functions such as dose actuation, solvent delivery, sample agitation and after which the user collects the sample manually. The process is ended with an automated drying procedure. The integration with FIA’s TriggerBox III gives the user full control of the flow process and relevant data recorded on file or printer. Ellipta ® is one of the devices on this product category, we have managed to overcome the challenges of getting a leak-tight fit between the device mouthpiece and the dose collector inlet. The inlet has a very precisely machined geometry which will provide an optimal contact and seal against the device mouthpiece. This principle can also be applied to, e.g., DUSA and adapters for the NGI induction port. Please enquire for more information. See also Turbuhaler ® implementation , but can be made for essentially all devices upon customer request. See also attached flyer for more information for in-depth information.

-

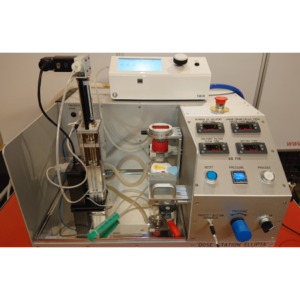

Dose Station Turbuhaler ®

This is our dedicated delivered dose uniformity test station for Turbuhaler ®, using the brilliant impinger filter dose collector. The latter is washable in-situ and can be ready for the next dose as part of the wet chemistry work-up procedure. The user works with the equipment in a fixed process which starts by the user placing the device in an inlet which mates with the dose collector. The inlet is a highly sophisticated construction with an inflatable gasket which seals around the mouthpiece. Above the gasket there are channels which efficiently rinses the gasket and the filter with solvent. The user is aided by the station with functions such as dose actuation, solvent delivery, sample agitation and dose collector cleaning, after which the user collects the sample manually. The process is ended with an automated drying procedure. The integration with FIA’s TriggerBox III gives the user full control of the flow process and relevant data recorded on file or printer. Turbuhaler ® is one of the devices on this product category, see also Ellipta ® implementation, but can be made for essentially all devices upon customer request. See also attached flyer for in-depth information.

-

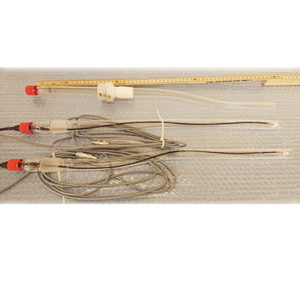

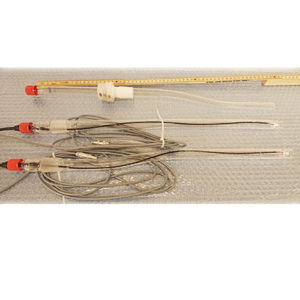

For use with our continuous infusion system or dual infusion systems.

For use with our continuous infusion system or dual infusion systems.

Provides dual check valves for two syringes, withdraw will pull fluid from a reservoir and infusion will output into a separate line.

The kit is pre-assembled - just attach the syringes.

Each dual check valve uses 15 cm. of 1/8" ID tubing connected to a Y connector, one for reservoir and one for output; each Y-connector has 1,5 m. of tubing to make connections to your application. Two 50 mL NormJect Syringes are included. -

ED Immersion Thermostat is a temperature control unit that ideally can be used for temperature control tasks within an internal bath up to 50 L. Temperatures can be easily read via the LED-display screen. An easy keypad (set point, arrow up and arrow down key) is used to enter a set point. The high-performance heating technology, gives a very short heating time. A powerful suction-pressure pump enables ideal circulation with external closed applications.

-

Volumetric dispenser with a programmable volume in the interval of 10 to 1100 ml. The volume may be repeated to pump several liters in portions. This function may be used for instance to repeatedly fill vessels.

On the picture is shown a product version with a stand. It may also be mounted on a stainless lab trolley or with the lower part under a table.

All parts in liquid contact are corrosion resistant, allowing handling of aggressive liquids and solvents. It is also available for dilution purposes with extra valves.

Easy to operate via touch panel. No PC is needed. Just type in the desired volume in ml and the dispenser will withdraw the volume from the container and dispense it from the outlet.

Different liquids will need different withdrawal and infusion (dispensing) speeds which is easily changed through the panel.

Exact dosage of liquid volumes is in the range of < 10 – 1100 ml. The set volume can be repeated, thus it is also possible to dispense for instance 999 x 1100 ml.

Standard deviation less than 0.02.

Volume accuracy and precision: fault < 0.5 ml in the interval 30 – 300 ml and in the interval 300 – 1100 ml < 0.4%.

The concept can be made in other configurations, such as compact models with shorter but broader cylinders, when a slighty less accurate delivery is acceptable. Lower volume ranges, e.g., 500 ml are also available.

-

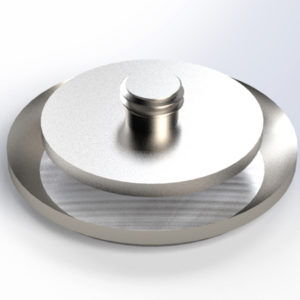

Equipment for abbreviated impactor measurement (AIM). For an introduction please read here about our automated concept for AIM (on our company homepage), download AB Fia folder Where the AIM Is Quality Control. The complete FSI consists of a housing, insert and a fine fraction collector with filters. The insert has a 5 micron cut-off at specified flow rate, specify between 30 to 100 L/min at increments of 5. Items are available both refurbished or as new, depending on stock situation. Trade Item Numbers: F5260 FSI Complete: Housing, insert and a fine fraction collector. Specify flow rate for insert L/min. Comes with 2 packs of 50 filters. F5261 Additional insert F5262 fine fraction collector, “filter housing”

Equipment for abbreviated impactor measurement (AIM). For an introduction please read here about our automated concept for AIM (on our company homepage), download AB Fia folder Where the AIM Is Quality Control. The complete FSI consists of a housing, insert and a fine fraction collector with filters. The insert has a 5 micron cut-off at specified flow rate, specify between 30 to 100 L/min at increments of 5. Items are available both refurbished or as new, depending on stock situation. Trade Item Numbers: F5260 FSI Complete: Housing, insert and a fine fraction collector. Specify flow rate for insert L/min. Comes with 2 packs of 50 filters. F5261 Additional insert F5262 fine fraction collector, “filter housing”