-

With this manifold you can regulate the flow of both vacuum (negative pressure) and pressurised flow while keeping the lab bench tidy. Typically used in combination with mixing inlet (Mixing Inlet - Air-Flow Moderating Inlet (AMI) - AB FIA Online Store) where a precise flow duration might not be needed. For the latter please see our line of critical flow controllers: Flow and Actuation Control - AB FIA Online Store It can come assembled with fittings and tubing and shut-off valves for vacuum and pressurised air. Describe your needs and we will come back with an offer.

With this manifold you can regulate the flow of both vacuum (negative pressure) and pressurised flow while keeping the lab bench tidy. Typically used in combination with mixing inlet (Mixing Inlet - Air-Flow Moderating Inlet (AMI) - AB FIA Online Store) where a precise flow duration might not be needed. For the latter please see our line of critical flow controllers: Flow and Actuation Control - AB FIA Online Store It can come assembled with fittings and tubing and shut-off valves for vacuum and pressurised air. Describe your needs and we will come back with an offer. -

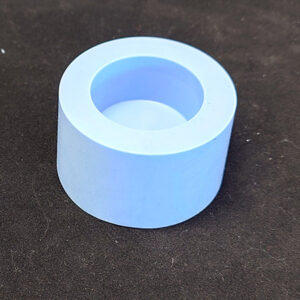

We offer the service of welding your NGI cups to the NGI tray. Many users find this practical in their everyday handling of the NGI. We have long experience of welding the cups with minimum material change. We inspect the cups before and after the welding to make sure the in-use specifications are upheld. You can send us your own NGI parts or we can take from our internal stock of NGI parts. Depending on the situation, we can agree on various guarantee-commitments.(See the images for further descriptions.)

-

We have broad and long experience of reparing impactors, predominantly the NGI. Examples are:

- Nickel coating of NGI body and pre-separator

- TiN layer on USP induction port and pre-separator tapered male ends

- Polish severely scratched surfaces, such as joints between impactor parts (the NGI stage 1 female entry port is vulnerable) and surfaces around the entry of the induction port. Any measures are discussed with the customers prior, since some parts simply have reached end-of-life.

- Reconditioning nozzles on stages where the holes regain their original specifications, or repairing complete stages. Which are verified by optical or mechanical inspections, or through method for determining stage pressure drop:Impactor Nozzle Diameter Measurement NGI

-

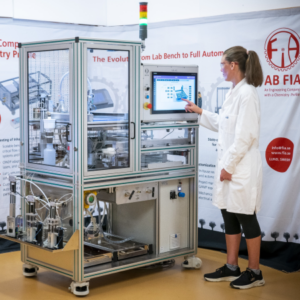

Automated Delivered Dose uniformity (DDU) and Waste station. A large number of inhalers is loaded into a magazine and the controller works down a list of operations such as delivered dose testing and waste dosing (between periods of the dosing regime). The technology builds on well-established process control equipment from, e.g., Siemens and Festo, why it sits well withing the customers existing support and maintenance organisation. Can be customized to your device. Read more here.

-

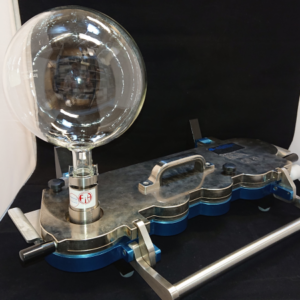

For nasal administration, expansion chamber as recommended by the FDA for the estimation of the deposition in the respiratory tract. The configuration consists of an expansion chamber (in which the nasal aerosol is generated) assembled to an impactor (e.g. an ACI, NGI, etc.). Three different sizes: 1 L for powder aerosols, 2 L and 5 L for liquid sprays. Comes with a clamp and adapter between glass and NGI. Optionally with a stand for the 5 L chamber. Adapters available for the insertion of the device.

-

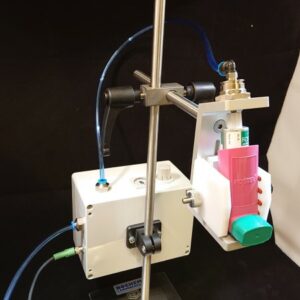

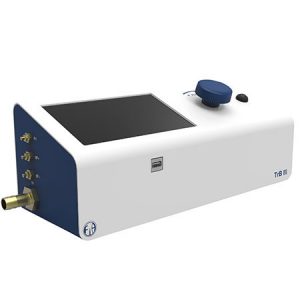

TrB III Trigger Box – All-in-One Flow Controller

The TrB III Trigger Box ensures compliance with standard pharmacopeial methods, both recording and storing key system parameters, including the actual flow rate and run duration. Many inhaler test methods rely on critical flow conditions across the flow control valve, aiming to ensure the same flow rate on each test. But the TrB III does more – actually measures the flow of each test – so, there are no assumptions.

A calibrated laminar flow element (LFE) internal to each TrB III enables the user to set the flow rate at the beginning of a test sequence; with this LFE, the TrB III then records the flow rate of each test, ensuring against drift, leaks, and other non-ideal behavior that may introduce variability in test results. The TrB III also records the other more traditional run-time parameters, such as the test duration, the pressure drop across the inhaler device (P1), and the flow control pressure ratio (P3/P2, critical flow if ≤ 0.5).1

Additional user-friendly functions are leak checking and synchronized device actuation by using the integrated output port. Device actuation enables the flow to start simultaneously with dose actuation of a metered-dose inhaler, allowing a user- defined, fixed flow volume for MDI total dose testing.

Download AB Fia folder Trigger Box TrB III.

Key features are:

- Flow actuation: 0-60 min, 0.1s resolution

- Actuation counter: Resettable 0-999

- Foot switch: Yes

- Display: 7” touch

- P1 measurement: Yes, 0-16 kPa

- P3/P2 measurement: Yes

- Flow measurement: Calibrated 0 – 120 l/min (operating range possibly higher)

- Automatic leak test: Yes

- Printable data: Prints new actuations continuously or print all actuations from reset.

- Date/time of first dose

- Instrument ID

- Instrument ver

- Flow ”on” time

- External relay timing

- Atmospheric pressure

- Dose number

- P1 and flow

- P3/P2 (if < 0.5)

- Relay output for actuation of external equipment: Yes, configurable timing of output relative vacuum opening.

- Displayed history of recent actuation data: All actuations from reset.

- Interfaces:

- Relay output for actuation of external equipment

- Foot switch actuator

- USB for CSV export

- Dimensions (cm): 34x13x13

Download the pdf TrB III – All in one Flow Controller

-

Glass Frit Impinger DUSA

Used as an alternative to the DUSA after proper equivalence testing (ask us how!). Used by many of the leading companies within OINDP testing. This filter comes in various forms but adheres to the principles which was published in a USP stimuli article 1993. 1 It lends itself to high-capacity testing and automation since it is washable with good recovery and minor carry-over.

- 1. Hugosson, S., J. Lindberg, T. Lööf, B. Olsson, ”Proposals for Standardized Testing of Powder Preparations for Inhalation”, Pharm Forum, Vol 19-3, 5458-66, 1993

-

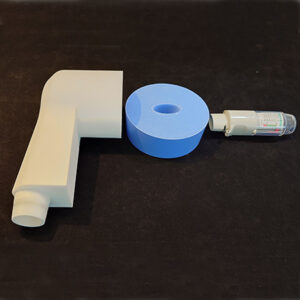

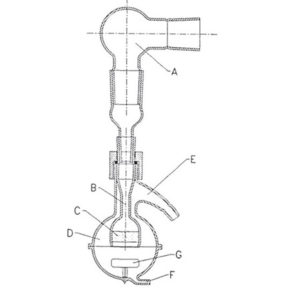

Dose Station Turbuhaler ®

This is our dedicated delivered dose uniformity test station for Turbuhaler ®, using the brilliant impinger filter dose collector. The latter is washable in-situ and can be ready for the next dose as part of the wet chemistry work-up procedure. The user works with the equipment in a fixed process which starts by the user placing the device in an inlet which mates with the dose collector. The inlet is a highly sophisticated construction with an inflatable gasket which seals around the mouthpiece. Above the gasket there are channels which efficiently rinses the gasket and the filter with solvent. The user is aided by the station with functions such as dose actuation, solvent delivery, sample agitation and dose collector cleaning, after which the user collects the sample manually. The process is ended with an automated drying procedure. The integration with FIA’s TriggerBox III gives the user full control of the flow process and relevant data recorded on file or printer. Turbuhaler ® is one of the devices on this product category, see also Ellipta ® implementation, but can be made for essentially all devices upon customer request. See also attached flyer for in-depth information.

-

This is our well-proven and appreciated flow controller with a timed shut-off of valve and high-quality regulating valve. See our other range of flow controllers here

-

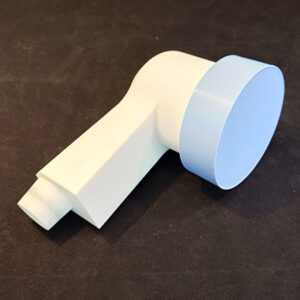

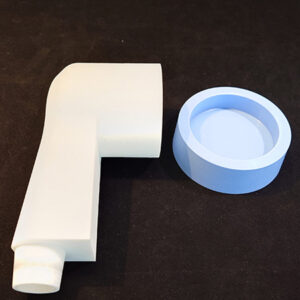

A convenient way to introduce a P1 tap to measure the pressure drop over a device according to pharmacopoeia. See example when applied to a waste station.