-

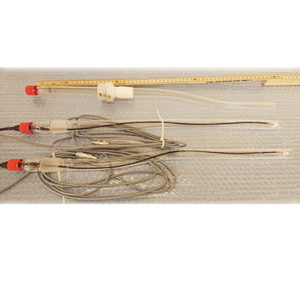

A convenient way to introduce a P1 tap to measure the pressure drop over a device according to pharmacopoeia. See example when applied to a waste station.

-

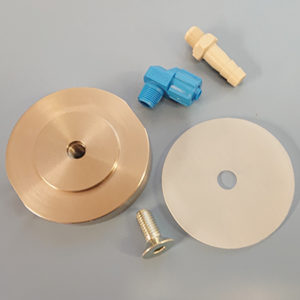

Andersen Blank Stage

To achieve an even distribution of a dose from an OINDP on a filter for dissolution testing [1], a blank stage is introduced next to the filter stage on the Andersen impactor. The blank stage (lower part in the picture) fits to the ordinary Andersen stage (upper part in the picture).

1. Sitaram P. Velagaa, Jelena Djuris, Sandra Cvijic, Stavroula Rozou, Paola Russo, Gaia Colombo Alessandra Rossi; European Journal of Pharmaceutical Sciences, ISSN: 0928-0987, Vol: 113, Page: 18-28

-

Automated Salt Deposition Monitor (ASDM)

Insulator flashover happens when soluble and/or non-soluble contaminants cover the insulator surface which results in a reduction of the surface resistance [1]. FIA’s ASDM helps to predict the contamination level on the outdoor ceramic insulators surface. This can help as a mean to warn overhead lines operators about the advent of insulator flashover.

The ASDM consists of an equipment with a pilot insulator exposed to the same condition as the operational insulators in a, e.g., converter station. Many stations are situated in demanding areas, typically close to a shore line. By frequently automatically monitoring the Equivalent Salt Deposit Density (ESDD) it helps the operators to understand the build-up of contaminants on the insulator surface. The ASDM also measures wind and wind direction, enabling it to give a prognosis of potential flash over conditions.

The equipment is class IP64 and all outdoor parts are compatible with the demanding environment, such acid proof steel AISI 316, equivalent to corrosivity class C5-M.

The user interface for monitoring and control may be positioned remotely in an adjacent building.

The equipment is a modernized version of historical constructions installed at, e.g., nuclear power plants. FIA’s equipment has passed detailed technical reviews by demanding customers and our service team has passed the high security screens and made installations at restricted locations.

Request a quote or send a line to i@fia.se and we can tell more.

1. Abdelrahman K. Abouzeid, Ayman El-Hag & Khaled Assaleh (2018) Equivalent Salt Deposit Density Prediction of Silicone Rubber Insulators Under Simulated Pollution Conditions, Electric Power Components and Systems, 46:10, 1123-1133, DOI: 10.1080/15325008.2018.1488303

-

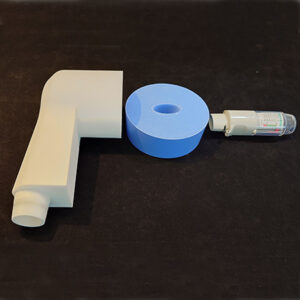

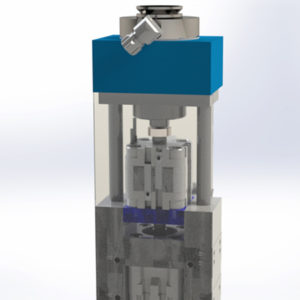

Automated Waste Station Turbuhaler/ICORes

can be customised according to your device, the example shown here is for Turbuhaler/ICORes. The station can be made to withdraw doses in different angles, i.e., different orientation of the device, to overcome “memory effects” of reservoir inhalers. Actuation can be by push, pull or as shown here, with a twist. The doses are collected on a high-capacity filter, with a holding capacity of about 10 g. The disposable filter is then safely and easily replaced. The integration with FIA’s TriggerBox III gives the user full control of the flow process and relevant data recorded on file or printer. Can be equipped with anti-static-device. See here for more information.

-

Patient Realistic Inhaler Testing

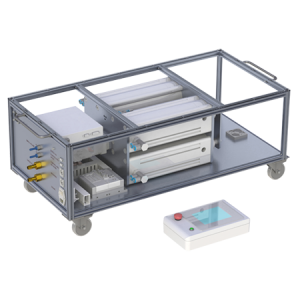

The F-SIG 6300 by AB FIA is a breathing profile generator that is capable of replaying complex breathing patterns. Thanks to a novel multi-cylinder design F-SIG 6300 enables generation of a number of clinical relevant patterns. F-SIG 6300 is not intended for clinical use on humans. The areas of operation are for instance: Testing of pharmaceutical inhalers and nebulizers with human breathing patterns. Characterization of cigarettes (smokers profiles). Rodent profiles and general respiratory research that includes very controlled breathing patterns.

User Friendly and Versatile

The F-SIG 6300 is operator-friendly and comes with a touch panel. Profiles, possibly recorded by FIA's Metivent software, are handled and modified in a spreadsheet (e.g. Excel) and the profile library is downloaded to the F-SIG 6300. The operator can thereafter, from the library of profiles, select desired profile on the panel and start the replay of the profile.

The Equipment:

F-SIG 6300 consists of a breathing profile generator built into a box with transparent plastic covers and placed on wheels. The control system of the multi-cylinder package is configured and operated by the user through the touch panel.

Capacity large volume: 0 - 6.3 liters

Capacity small volume: 0 - 0.1 liters

Voltage: 95 - 255VAC, 50 - 60Hz, 6.5A

Dimensions HxWxD: 380x1036x480 mm, Touch Panel: 80x280x170 mmDownload the pdf Patient Realistic Inhaler Testing

-

The standard FIA Chewing Apparatus DRT has a fixed operation for the masticating jaw´s movements. The linear movements Press and Open are achieved by a pneumatic cylinder that is forced to reach the end positions of the cylinder. In a similar way the twist motion must always reach the end position (Twist). (The positions of the twist cylinder are Twist and Regain, where only Twist is acting on the chewing gum by torque forces). The PTM module enables the ability to register pressure and torque forces during the mastication of chewing gums. There is also the possibility to set a maximum pressure value before the chewing sequence proceed with the twist movement. A PTM module can optionally be added to the apparatus which enable both pressure control with monitoring and torque monitoring. If the maximum value is reached for the pressure on the gum, the twisting movement of the jaws is achieved even if the end position of the Press-movement is not reached. With a hard gum, the gap between the jaws must not necessarily be reached before Twist motion is applied on the gum. The PTM module must be ordered for various amount of chewing cells during purchase of a new Chewing Apparatus. It can’t be retrofitted.

-

The Controlled Pump is designed to run 32 different pump programs that are easy selectable by two thumb wheels on the front panel. A program consists of one infusion motion and one withdrawal motion which are both configurable with stroke length and speed.

Start a selected pump program by press of the green “START/STOP” push button at the front panel. The pump will start infuse with parameters from the selected pump program. When the pump reach the programmed end position, it will immediately withdraw and then infuse and so on, as long as the latched push button is in its inner position.

Specifications

Dimensions: 122 x 140 x 350 mm. (WxDxH)

Weight: 4,4 kg.

Power supply: External power supply, 24 VDC 2,5 A

Glass syringe connection for external equipment: Luer Lock

Maximum infusion/withdrawal volume: 20 ml.

Maximum infusion/withdrawal rate (measured directly against atmosphere) 50 ml/s.

Lowest infusion/withdrawal rate (measured directly against atmosphere) 6 ml/s. -

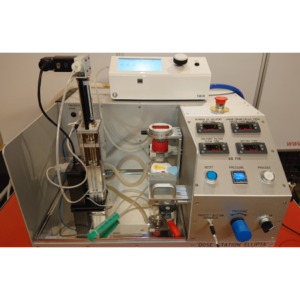

Dose Station Ellipta ®

This is our dedicated delivered dose uniformity test station for Ellipta ®, using the brilliant impinger filter dose collector. The latter is washable in-situ and can be ready for the next dose as part of the wet chemistry work-up procedure. The user works with the equipment in a fixed process which starts by the user placing the device in a nest which mates with the dose collector inlet. Thereafter aided by the station with functions such as dose actuation, solvent delivery, sample agitation and after which the user collects the sample manually. The process is ended with an automated drying procedure. The integration with FIA’s TriggerBox III gives the user full control of the flow process and relevant data recorded on file or printer. Ellipta ® is one of the devices on this product category, see also Turbuhaler ® implementation , but can be made for essentially all devices upon customer request. See also attached flyer for more information for in-depth information.

-

Dose Station Turbuhaler ®

This is our dedicated delivered dose uniformity test station for Turbuhaler ®, using the brilliant impinger filter dose collector. The latter is washable in-situ and can be ready for the next dose as part of the wet chemistry work-up procedure. The user works with the equipment in a fixed process which starts by the user placing the device in an inlet which mates with the dose collector. The inlet is a highly sophisticated construction with an inflatable gasket which seals around the mouthpiece. Above the gasket there are channels which efficiently rinses the gasket and the filter with solvent. The user is aided by the station with functions such as dose actuation, solvent delivery, sample agitation and dose collector cleaning, after which the user collects the sample manually. The process is ended with an automated drying procedure. The integration with FIA’s TriggerBox III gives the user full control of the flow process and relevant data recorded on file or printer. Turbuhaler ® is one of the devices on this product category, see also Ellipta ® implementation, but can be made for essentially all devices upon customer request. See also attached flyer for in-depth information.