Patient Realistic Inhaler Testing

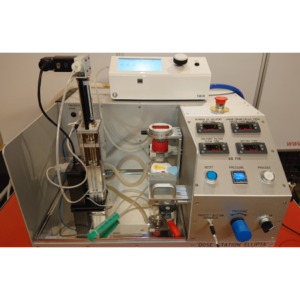

The F-SIG 6300 by AB FIA is a breathing profile generator that is capable of replaying complex breathing patterns. Thanks to a novel multi-cylinder design F-SIG 6300 enables generation of a number of clinical relevant patterns. F-SIG 6300 is not intended for clinical use on humans. The areas of operation are for instance: Testing of pharmaceutical inhalers and nebulizers with human breathing patterns. Characterization of cigarettes (smokers profiles). Rodent profiles and general respiratory research that includes very controlled breathing patterns.

User Friendly and Versatile

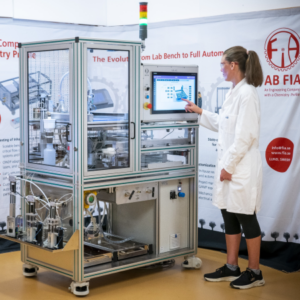

The F-SIG 6300 is operator-friendly and comes with a touch panel. Profiles, possibly recorded by FIA's Metivent software, are handled and modified in a spreadsheet (e.g. Excel) and the profile library is downloaded to the F-SIG 6300. The operator can thereafter, from the library of profiles, select desired profile on the panel and start the replay of the profile.

The Equipment:

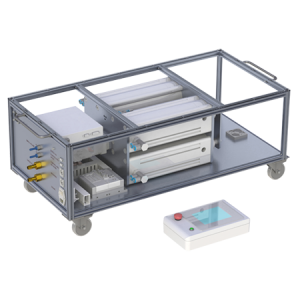

F-SIG 6300 consists of a breathing profile generator built into a box with transparent plastic covers and placed on wheels. The control system of the multi-cylinder package is configured and operated by the user through the touch panel.

Capacity large volume: 0 - 6.3 liters

Capacity small volume: 0 - 0.1 liters

Voltage: 95 - 255VAC, 50 - 60Hz, 6.5A

Dimensions HxWxD: 380x1036x480 mm, Touch Panel: 80x280x170 mm

Download the pdf Patient Realistic Inhaler Testing