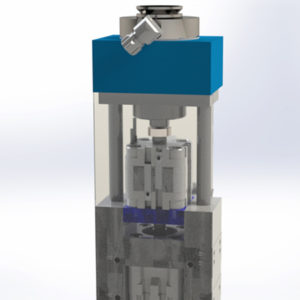

The standard FIA Chewing Apparatus DRT has a fixed operation for the masticating jaw´s movements. The linear movements Press and Open are achieved by a pneumatic cylinder that is forced to reach the end positions of the cylinder. In a similar way the twist motion must always reach the end position (Twist). (The positions of the twist cylinder are Twist and Regain, where only Twist is acting on the chewing gum by torque forces). The PTM module enables the ability to register pressure and torque forces during the mastication of chewing gums. There is also the possibility to set a maximum pressure value before the chewing sequence proceed with the twist movement. A PTM module can optionally be added to the apparatus which enable both pressure control with monitoring and torque monitoring. If the maximum value is reached for the pressure on the gum, the twisting movement of the jaws is achieved even if the end position of the Press-movement is not reached. With a hard gum, the gap between the jaws must not necessarily be reached before Twist motion is applied on the gum. The PTM module must be ordered for various amount of chewing cells during purchase of a new Chewing Apparatus. It can’t be retrofitted.

-

The Controlled Pump is designed to run 32 different pump programs that are easy selectable by two thumb wheels on the front panel. A program consists of one infusion motion and one withdrawal motion which are both configurable with stroke length and speed.

Start a selected pump program by press of the green “START/STOP” push button at the front panel. The pump will start infuse with parameters from the selected pump program. When the pump reach the programmed end position, it will immediately withdraw and then infuse and so on, as long as the latched push button is in its inner position.

Specifications

Dimensions: 122 x 140 x 350 mm. (WxDxH)

Weight: 4,4 kg.

Power supply: External power supply, 24 VDC 2,5 A

Glass syringe connection for external equipment: Luer Lock

Maximum infusion/withdrawal volume: 20 ml.

Maximum infusion/withdrawal rate (measured directly against atmosphere) 50 ml/s.

Lowest infusion/withdrawal rate (measured directly against atmosphere) 6 ml/s. -

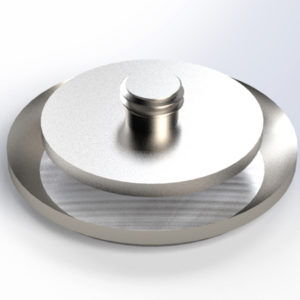

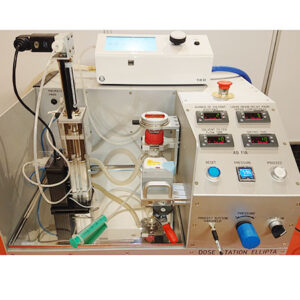

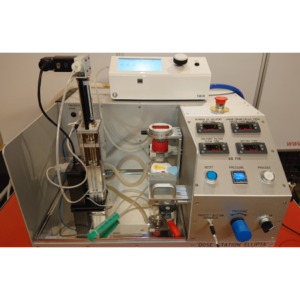

Dose Station Ellipta ®

This is our dedicated delivered dose uniformity test station for Ellipta ®, using the brilliant impinger filter dose collector. The latter is washable in-situ and can be ready for the next dose as part of the wet chemistry work-up procedure. The user works with the equipment in a fixed process which starts by the user placing the device in a nest which mates with the dose collector inlet. Thereafter aided by the station with functions such as dose actuation, solvent delivery, sample agitation and after which the user collects the sample manually. The process is ended with an automated drying procedure. The integration with FIA’s TriggerBox III gives the user full control of the flow process and relevant data recorded on file or printer. Ellipta ® is one of the devices on this product category, we have managed to overcome the challenges of getting a leak-tight fit between the device mouthpiece and the dose collector inlet. The inlet has a very precisely machined geometry which will provide an optimal contact and seal against the device mouthpiece. This principle can also be applied to, e.g., DUSA and adapters for the NGI induction port. Please enquire for more information. See also Turbuhaler ® implementation , but can be made for essentially all devices upon customer request. See also attached flyer for more information for in-depth information.