-

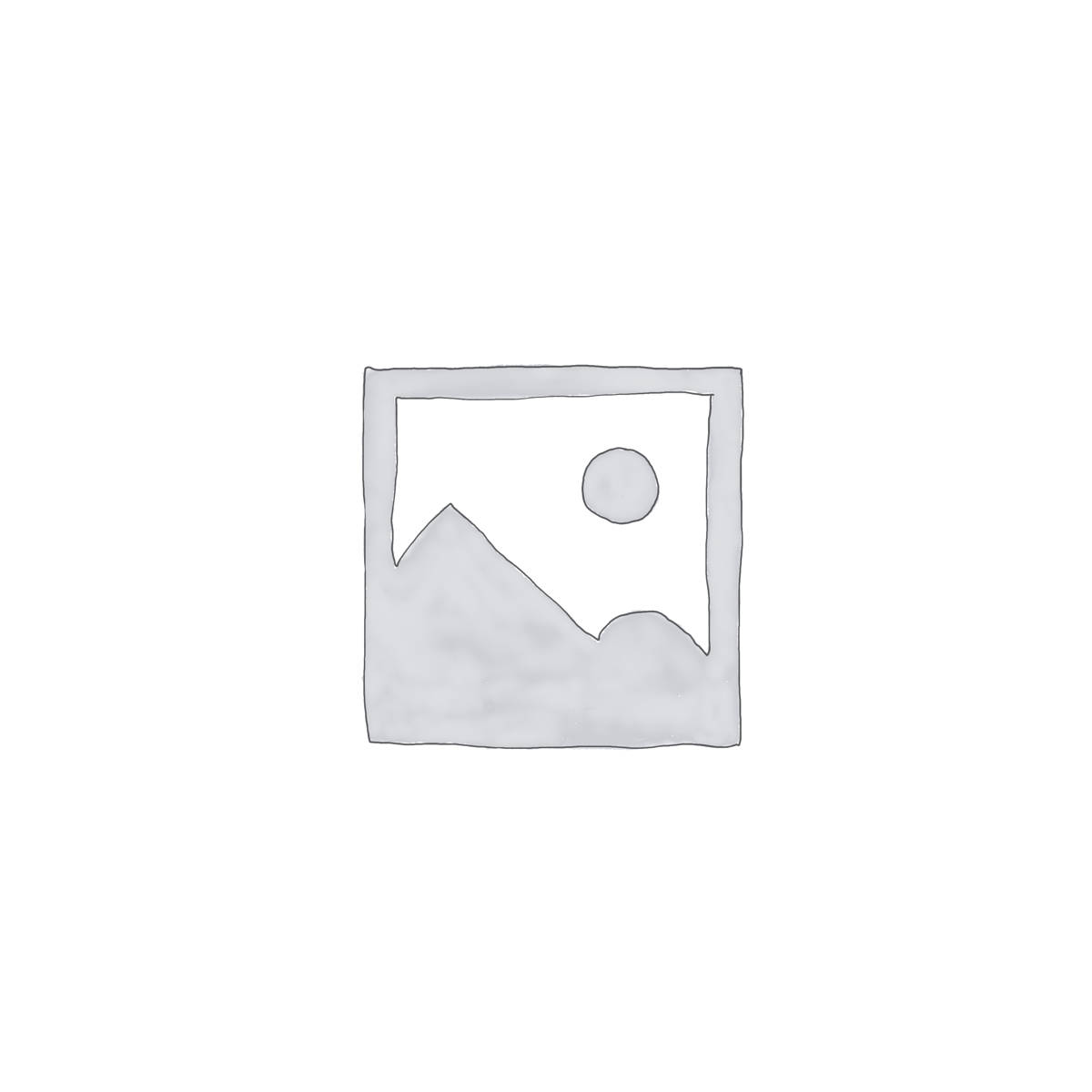

Trigger Box Model I – Basic

This model gives the analyst the basic functionality in a very compact and easily managed format.

Key features are:

- Flow actuation: 0-99 min, 0.1s resolution

- Actuation counter: Resettable, 8 digits

- Foot switch: Optional

- Display: 4 and 8 digits

- P1 Measurement: No

- P3/P2 Measurement: No

- Flow Measurement: No

- dP (e.g. stage dP): No

- Printable data: No

- Relay output for actuation of external equipment: No

- Displayed history of recent actuation data: No

- USB memory stick export: No

- Automatic leak test: No

- Dimensions (cm): 23x13x13

-

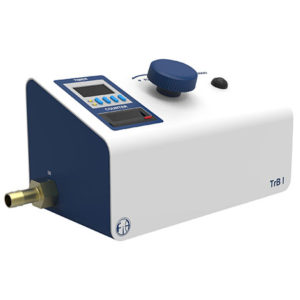

Trigger Box Model II – Critical Flow Controller

This model builds on the functions of Model I with the addition of differential pressure transducers for measuring and displaying pressure at P1, P2, and P3.

Key features are:

- Flow actuation: 0-60 min, 0.1s resolution

- Actuation counter: Resettable 0-999

- Foot switch: Yes

- Display: 4.3” touch

- P1 Measurement: Yes, 0-16 kPa

- P3/P2 Measurement: Yes

- Flow Measurement: No

- dP (e.g. stage dP): No

- Printable data: Prints new actuations continuously

- Flow ”on” time

- Dose number

- P1

- P3/P2 (if < 0.5)

- Relay output for actuation of external equipment: No

- Displayed history of recent actuation data: Last 3 actuations

- USB memory stick export: No

- Automatic leak test: No

- Dimensions (cm): 23x13x13

-

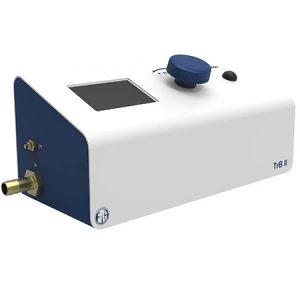

TrB III Trigger Box Delta – All-in-One Flow Controller

The TrB III Trigger Box ensures compliance with standard pharmacopeial methods, both recording and storing key system parameters, including the actual flow rate and run duration. Many inhaler test methods rely on critical flow conditions across the flow control valve, aiming to ensure the same flow rate on each test. But the TrB III does more – actually measures the flow of each test – so, there are no assumptions.

A calibrated laminar flow element (LFE) internal to each TrB III enables the user to set the flow rate at the beginning of a test sequence; with this LFE, the TrB III then records the flow rate of each test, ensuring against drift, leaks, and other non-ideal behavior that may introduce variability in test results. The TrB III also records the other more traditional run-time parameters, such as the test duration, the pressure drop across the inhaler device (P1), and the flow control pressure ratio (P3/P2, critical flow if ≤ 0.5). The Delta version can measure pressure drop over, e.g., individual impactor stages to detect blockage, using additional internal sensors.1

Additional user-friendly functions are leak checking and synchronized device actuation by using the integrated output port. Device actuation enables the flow to start simultaneously with dose actuation of a metered-dose inhaler, allowing a user- defined, fixed flow volume for MDI total dose testing.

Download AB Fia folder Trigger Box TrB III.

Key features are:

- Flow actuation: 0-60 min, 0.1s resolution

- Actuation counter: Resettable 0-999

- Foot switch: Yes

- Display: 7” touch

- P1 measurement: Yes, 0-16 kPa

- P3/P2 measurement: Yes

- Flow measurement: Calibrated 0 – 120 l/min (operating range possibly higher)

- dP (e.g. stage dP): Yes, high precision 0-6 kPa

- Automatic leak test: Yes

- Printable data: Prints new actuations continuously or print all actuations from reset.

- Date/time of first dose

- Instrument ID

- Instrument ver

- Flow ”on” time

- External relay timing

- Atmospheric pressure

- Dose number

- P1 and flow

- P3/P2 (if < 0.5)

- dP (stage pressure drop)

- Relay output for actuation of external equipment: Yes, configurable timing of output relative vacuum opening.

- Displayed history of recent actuation data: All actuations from reset.

- Interfaces:

- Relay output for actuation of external equipment

- Foot switch actuator

- USB for CSV export

- Dimensions (cm): 34x13x13

Download the pdf TrB III – All in one Flow Controller

-

Volumetric dispenser with a programmable volume in the interval of 10 to 1100 ml. The volume may be repeated to pump several liters in portions. This function may be used for instance to repeatedly fill vessels.

On the picture is shown a product version with a stand. It may also be mounted on a stainless lab trolley or with the lower part under a table.

All parts in liquid contact are corrosion resistant, allowing handling of aggressive liquids and solvents. It is also available for dilution purposes with extra valves.

Easy to operate via touch panel. No PC is needed. Just type in the desired volume in ml and the dispenser will withdraw the volume from the container and dispense it from the outlet.

Different liquids will need different withdrawal and infusion (dispensing) speeds which is easily changed through the panel.

Exact dosage of liquid volumes is in the range of < 10 – 1100 ml. The set volume can be repeated, thus it is also possible to dispense for instance 999 x 1100 ml.

Standard deviation less than 0.02.

Volume accuracy and precision: fault < 0.5 ml in the interval 30 – 300 ml and in the interval 300 – 1100 ml < 0.4%.

The concept can be made in other configurations, such as compact models with shorter but broader cylinders, when a slighty less accurate delivery is acceptable. Lower volume ranges, e.g., 500 ml are also available.

-

The Controlled Pump is designed to run 32 different pump programs that are easy selectable by two thumb wheels on the front panel. A program consists of one infusion motion and one withdrawal motion which are both configurable with stroke length and speed.

Start a selected pump program by press of the green “START/STOP” push button at the front panel. The pump will start infuse with parameters from the selected pump program. When the pump reach the programmed end position, it will immediately withdraw and then infuse and so on, as long as the latched push button is in its inner position.

Specifications

Dimensions: 122 x 140 x 350 mm. (WxDxH)

Weight: 4,4 kg.

Power supply: External power supply, 24 VDC 2,5 A

Glass syringe connection for external equipment: Luer Lock

Maximum infusion/withdrawal volume: 20 ml.

Maximum infusion/withdrawal rate (measured directly against atmosphere) 50 ml/s.

Lowest infusion/withdrawal rate (measured directly against atmosphere) 6 ml/s. -

Key features:

- Can be operated in a series

- Very accurate with a repeatability of 0.04% RSD

- Simplicity in design

- Long life time of dispensing equipment

- Constructed of glass and teflon

- Suitable for integration in robotic systems

- Can be ordered on a mobile platform for best working environment

- Full volume each stroke

- Impact time 10-20 sec

- No PLC nor computer dependent, but can be easily connected

All dispensers require compressed air of 6-8 bar.

-

Key features:

- Can be operated in a series

- Very accurate with a repeatability of 0.04% RSD

- Simplicity in design

- Long life time of dispensing equipment

- Constructed of glass and teflon

- Suitable for integration in robotic systems

- Can be ordered on a mobile platform for best working environment

- Full volume each stroke

- Impact time 10-20 sec

- No PLC nor computer dependent, but can be easily connected

All dispensers require compressed air of 6-8 bar.

-

Inhaler mouthpiece adapter IP red to impactor induction port.

Inhaler mouthpiece adapter IP red to impactor induction port.

Material: Red silicone (softer and more "forgiving"). FIA also sells impactors and induction ports. -

Inhaler mouthpiece adapter IP blue to impactor induction port.

Inhaler mouthpiece adapter IP blue to impactor induction port.

Material: Blue silicone (harder and more durable). FIA also sells impactors and induction ports.