-

SGE PTFE Tipped Plunger Gas Tight Glass Syringes

SGE PTFE Tipped Plunger Gas Tight Glass Syringes

A PTFE tip plunger minimizes carryover and prevents particulate matter from getting between the plunger and barrel by effectively wiping the barrel inner diameter during the plunger stroke. PTFE tipped plungers are suitable for both liquid and gas samples. Individually boxed. Pistons and barrels are interchangeable.

100uL

Fixed Metal Luer Lock

27.6 bar

70deg-Celcius -

SGE PTFE Tipped Plunger Gas Tight Glass Syringes

SGE PTFE Tipped Plunger Gas Tight Glass Syringes

A PTFE tip plunger minimizes carryover and prevents particulate matter from getting between the plunger and barrel by effectively wiping the barrel inner diameter during the plunger stroke. PTFE tipped plungers are suitable for both liquid and gas samples. Individually boxed. Pistons and barrels are interchangeable.

250uL

Fixed Metal Luer Lock

27.6 bar

70deg-Celcius -

SGE PTFE Tipped Plunger Gas Tight Glass Syringes

SGE PTFE Tipped Plunger Gas Tight Glass Syringes

A PTFE tip plunger minimizes carryover and prevents particulate matter from getting between the plunger and barrel by effectively wiping the barrel inner diameter during the plunger stroke. PTFE tipped plungers are suitable for both liquid and gas samples. Individually boxed. Pistons and barrels are interchangeable.

1mL

Fixed Metal Luer Lock

27.6 bar

70deg-Celcius -

SGE PTFE Tipped Plunger Gas Tight Glass Syringes

SGE PTFE Tipped Plunger Gas Tight Glass Syringes

A PTFE tip plunger minimizes carryover and prevents particulate matter from getting between the plunger and barrel by effectively wiping the barrel inner diameter during the plunger stroke. PTFE tipped plungers are suitable for both liquid and gas samples. Individually boxed. Pistons and barrels are interchangeable.

2.5mL

Fixed Metal Luer Lock

27.6 bar

70deg-Celcius -

SGE PTFE Tipped Plunger Gas Tight Glass Syringes

SGE PTFE Tipped Plunger Gas Tight Glass Syringes

A PTFE tip plunger minimizes carryover and prevents particulate matter from getting between the plunger and barrel by effectively wiping the barrel inner diameter during the plunger stroke. PTFE tipped plungers are suitable for both liquid and gas samples. Individually boxed. Pistons and barrels are interchangeable.

5mL

Fixed Metal Luer Lock

27.6 bar

70deg-Celcius -

Take Your Pump Control to the Next Level!

Take Your Pump Control to the Next Level!

SyringePumpPro enables you to connect multiple pumps to your computer and control them individually or as a group. You can automatically monitor all pump parameters without having to enter any commands. You can configure and control multi-pump protocols, log pump activity and send commands to selected pumps. Get to your results faster.- Constant monitoring of pump parameters

- See pump programs as they execute

- No more re-typing of commands in terminal software

- Send commands to one or many pumps

- Excellent support & service

- OEM Pump? No Keypad? You need SyringePumpPro!

-

For use with our continuous infusion system or dual infusion systems.

For use with our continuous infusion system or dual infusion systems.

Provides dual check valves for two syringes, withdraw will pull fluid from a reservoir and infusion will output into a separate line.

The kit is pre-assembled - just attach the syringes.

Each dual check valve uses 15 cm. of 1/8" ID tubing connected to a Y connector, one for reservoir and one for output; each Y-connector has 1,5 m. of tubing to make connections to your application. Two 50 mL NormJect Syringes are included. -

Allows full control of pump or other device from a computer

Allows full control of pump or other device from a computer

DB-9 adapter connects to 9-pin serial port (25-pin adapters available upon request)

Utilizes the RS-232 communications port of device

Quick and easy setup

Add to basket Details Allows full control of pump or other device from a computer

Allows full control of pump or other device from a computer

DB-9 adapter connects to 9-pin serial port (25-pin adapters available upon request)

Utilizes the RS-232 communications port of device

Quick and easy setup

Add to basket Details Used for creating a continuous infusion system, dual infusion system, or one of the other 2 pump automation modes.

Used for creating a continuous infusion system, dual infusion system, or one of the other 2 pump automation modes.

Establishes a communications link between two pumps using the RS-232 serial ports on the pumps.

Replaces cable CBL-TTL-1, unless the use of the TTL ports for synchronization is preferred

Download User Manual

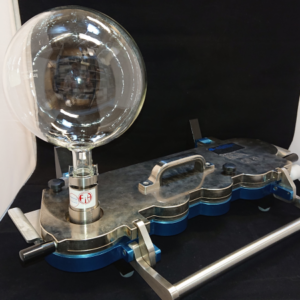

For nasal administration, expansion chamber as recommended by the FDA for the estimation of the deposition in the respiratory tract. The configuration consists of an expansion chamber (in which the nasal aerosol is generated) assembled to an impactor (e.g. an ACI, NGI, etc.). Three different sizes: 1 L for powder aerosols, 2 L and 5 L for liquid sprays. Comes with a clamp and adapter between glass and NGI. Optionally with a stand for the 5 L chamber. Adapters available for the insertion of the device.

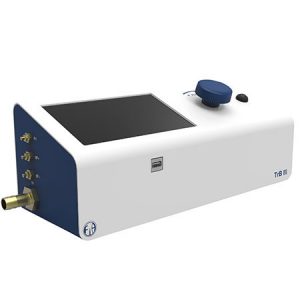

TrB III Trigger Box – All-in-One Flow Controller

The TrB III Trigger Box ensures compliance with standard pharmacopeial methods, both recording and storing key system parameters, including the actual flow rate and run duration. Many inhaler test methods rely on critical flow conditions across the flow control valve, aiming to ensure the same flow rate on each test. But the TrB III does more – actually measures the flow of each test – so, there are no assumptions.

A calibrated laminar flow element (LFE) internal to each TrB III enables the user to set the flow rate at the beginning of a test sequence; with this LFE, the TrB III then records the flow rate of each test, ensuring against drift, leaks, and other non-ideal behavior that may introduce variability in test results. The TrB III also records the other more traditional run-time parameters, such as the test duration, the pressure drop across the inhaler device (P1), and the flow control pressure ratio (P3/P2, critical flow if ≤ 0.5).1

Additional user-friendly functions are leak checking and synchronized device actuation by using the integrated output port. Device actuation enables the flow to start simultaneously with dose actuation of a metered-dose inhaler, allowing a user- defined, fixed flow volume for MDI total dose testing.

Download AB Fia folder Trigger Box TrB III.

Key features are:

- Flow actuation: 0-60 min, 0.1s resolution

- Actuation counter: Resettable 0-999

- Foot switch: Yes

- Display: 7” touch

- P1 measurement: Yes, 0-16 kPa

- P3/P2 measurement: Yes

- Flow measurement: Calibrated 0 – 120 l/min (operating range possibly higher)

- Automatic leak test: Yes

- Printable data: Prints new actuations continuously or print all actuations from reset.

- Date/time of first dose

- Instrument ID

- Instrument ver

- Flow ”on” time

- External relay timing

- Atmospheric pressure

- Dose number

- P1 and flow

- P3/P2 (if < 0.5)

- Relay output for actuation of external equipment: Yes, configurable timing of output relative vacuum opening.

- Displayed history of recent actuation data: All actuations from reset.

- Interfaces:

- Relay output for actuation of external equipment

- Foot switch actuator

- USB for CSV export

- Dimensions (cm): 34x13x13

Download the pdf TrB III – All in one Flow Controller

Glass Frit Impinger DUSA

Used as an alternative to the DUSA after proper equivalence testing (ask us how!). Used by many of the leading companies within OINDP testing. This filter comes in various forms but adheres to the principles which was published in a USP stimuli article 1993. 1 It lends itself to high-capacity testing and automation since it is washable with good recovery and minor carry-over.

- 1. Hugosson, S., J. Lindberg, T. Lööf, B. Olsson, ”Proposals for Standardized Testing of Powder Preparations for Inhalation”, Pharm Forum, Vol 19-3, 5458-66, 1993

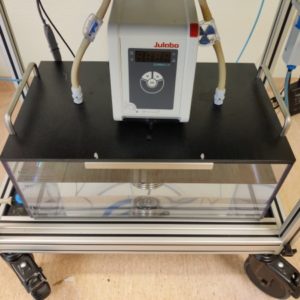

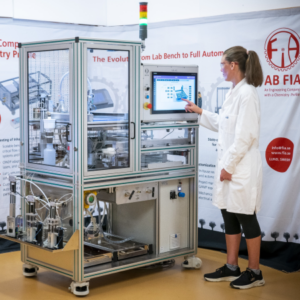

Dose Station Turbuhaler ®

This is our dedicated delivered dose uniformity test station for Turbuhaler ®, using the brilliant impinger filter dose collector. The latter is washable in-situ and can be ready for the next dose as part of the wet chemistry work-up procedure. The user works with the equipment in a fixed process which starts by the user placing the device in an inlet which mates with the dose collector. The inlet is a highly sophisticated construction with an inflatable gasket which seals around the mouthpiece. Above the gasket there are channels which efficiently rinses the gasket and the filter with solvent. The user is aided by the station with functions such as dose actuation, solvent delivery, sample agitation and dose collector cleaning, after which the user collects the sample manually. The process is ended with an automated drying procedure. The integration with FIA’s TriggerBox III gives the user full control of the flow process and relevant data recorded on file or printer. Turbuhaler ® is one of the devices on this product category, see also Ellipta ® implementation, but can be made for essentially all devices upon customer request. See also attached flyer for in-depth information.

Title