-

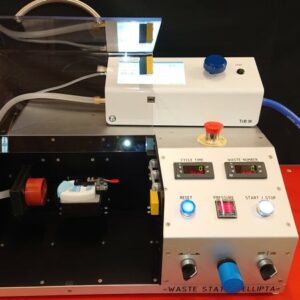

Waste Station Ellipta

This is our dedicated waste station for Ellipta. The user puts the Ellipta in a nest and closes a safety cover. The station then automatically mates the inhaler with the mouthpiece adapter, withdraws dose and then reverts. The process is repeated according to a user defined number, with selectable delay-time in between. The doses are collected on a high-capacity filter, with a holding capacity of about 10 g. The disposable filter is then safely and easily replaced. The integration with FIA’s TriggerBox III gives the user full control of the flow process and relevant data recorded on file or printer. Can be equipped with anti-static-device. See here for more information.

-

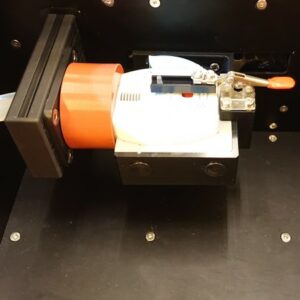

Waste Collection Station

Our basic yet efficient and flexible waste collection station. The user loads the dose and inserts the device into a dedicated mouthpiece adapter. The doses are collected on a high-capacity filter, with a holding capacity of about 10 g. The disposable filter is then safely and easily replaced. The integration with FIA’s TriggerBox III gives the user full control of the flow process and relevant data recorded on file or printer. Can be equipped with anti-static-device.

-

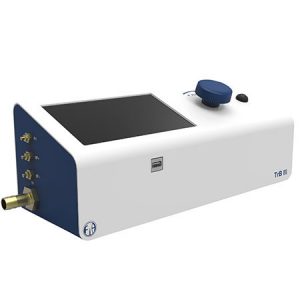

TrB III Trigger Box Delta – All-in-One Flow Controller

The TrB III Trigger Box ensures compliance with standard pharmacopeial methods, both recording and storing key system parameters, including the actual flow rate and run duration. Many inhaler test methods rely on critical flow conditions across the flow control valve, aiming to ensure the same flow rate on each test. But the TrB III does more – actually measures the flow of each test – so, there are no assumptions.

A calibrated laminar flow element (LFE) internal to each TrB III enables the user to set the flow rate at the beginning of a test sequence; with this LFE, the TrB III then records the flow rate of each test, ensuring against drift, leaks, and other non-ideal behavior that may introduce variability in test results. The TrB III also records the other more traditional run-time parameters, such as the test duration, the pressure drop across the inhaler device (P1), and the flow control pressure ratio (P3/P2, critical flow if ≤ 0.5). The Delta version can measure pressure drop over, e.g., individual impactor stages to detect blockage, using additional internal sensors.1

Additional user-friendly functions are leak checking and synchronized device actuation by using the integrated output port. Device actuation enables the flow to start simultaneously with dose actuation of a metered-dose inhaler, allowing a user- defined, fixed flow volume for MDI total dose testing.

Download AB Fia folder Trigger Box TrB III.

Key features are:

- Flow actuation: 0-60 min, 0.1s resolution

- Actuation counter: Resettable 0-999

- Foot switch: Yes

- Display: 7” touch

- P1 measurement: Yes, 0-16 kPa

- P3/P2 measurement: Yes

- Flow measurement: Calibrated 0 – 120 l/min (operating range possibly higher)

- dP (e.g. stage dP): Yes, high precision 0-6 kPa

- Automatic leak test: Yes

- Printable data: Prints new actuations continuously or print all actuations from reset.

- Date/time of first dose

- Instrument ID

- Instrument ver

- Flow ”on” time

- External relay timing

- Atmospheric pressure

- Dose number

- P1 and flow

- P3/P2 (if < 0.5)

- dP (stage pressure drop)

- Relay output for actuation of external equipment: Yes, configurable timing of output relative vacuum opening.

- Displayed history of recent actuation data: All actuations from reset.

- Interfaces:

- Relay output for actuation of external equipment

- Foot switch actuator

- USB for CSV export

- Dimensions (cm): 34x13x13

Download the pdf TrB III – All in one Flow Controller

-

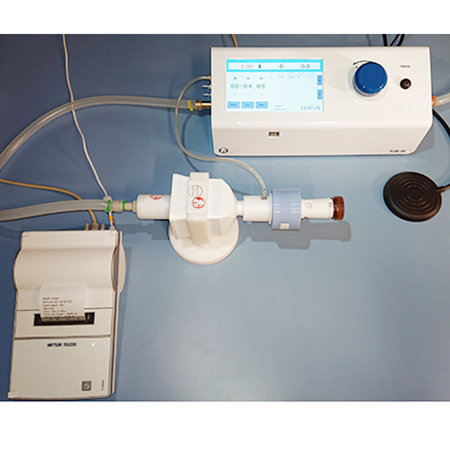

TrB III Trigger Box – All-in-One Flow Controller

The TrB III Trigger Box ensures compliance with standard pharmacopeial methods, both recording and storing key system parameters, including the actual flow rate and run duration. Many inhaler test methods rely on critical flow conditions across the flow control valve, aiming to ensure the same flow rate on each test. But the TrB III does more – actually measures the flow of each test – so, there are no assumptions.

A calibrated laminar flow element (LFE) internal to each TrB III enables the user to set the flow rate at the beginning of a test sequence; with this LFE, the TrB III then records the flow rate of each test, ensuring against drift, leaks, and other non-ideal behavior that may introduce variability in test results. The TrB III also records the other more traditional run-time parameters, such as the test duration, the pressure drop across the inhaler device (P1), and the flow control pressure ratio (P3/P2, critical flow if ≤ 0.5).1

Additional user-friendly functions are leak checking and synchronized device actuation by using the integrated output port. Device actuation enables the flow to start simultaneously with dose actuation of a metered-dose inhaler, allowing a user- defined, fixed flow volume for MDI total dose testing.

Download AB Fia folder Trigger Box TrB III.

Key features are:

- Flow actuation: 0-60 min, 0.1s resolution

- Actuation counter: Resettable 0-999

- Foot switch: Yes

- Display: 7” touch

- P1 measurement: Yes, 0-16 kPa

- P3/P2 measurement: Yes

- Flow measurement: Calibrated 0 – 120 l/min (operating range possibly higher)

- Automatic leak test: Yes

- Printable data: Prints new actuations continuously or print all actuations from reset.

- Date/time of first dose

- Instrument ID

- Instrument ver

- Flow ”on” time

- External relay timing

- Atmospheric pressure

- Dose number

- P1 and flow

- P3/P2 (if < 0.5)

- Relay output for actuation of external equipment: Yes, configurable timing of output relative vacuum opening.

- Displayed history of recent actuation data: All actuations from reset.

- Interfaces:

- Relay output for actuation of external equipment

- Foot switch actuator

- USB for CSV export

- Dimensions (cm): 34x13x13

Download the pdf TrB III – All in one Flow Controller

-

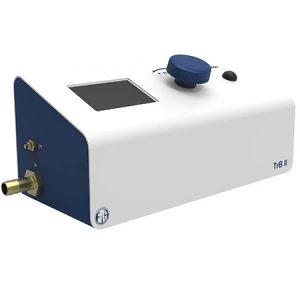

Trigger Box Model II – Critical Flow Controller

This model builds on the functions of Model I with the addition of differential pressure transducers for measuring and displaying pressure at P1, P2, and P3.

Key features are:

- Flow actuation: 0-60 min, 0.1s resolution

- Actuation counter: Resettable 0-999

- Foot switch: Yes

- Display: 4.3” touch

- P1 Measurement: Yes, 0-16 kPa

- P3/P2 Measurement: Yes

- Flow Measurement: No

- dP (e.g. stage dP): No

- Printable data: Prints new actuations continuously

- Flow ”on” time

- Dose number

- P1

- P3/P2 (if < 0.5)

- Relay output for actuation of external equipment: No

- Displayed history of recent actuation data: Last 3 actuations

- USB memory stick export: No

- Automatic leak test: No

- Dimensions (cm): 23x13x13

-

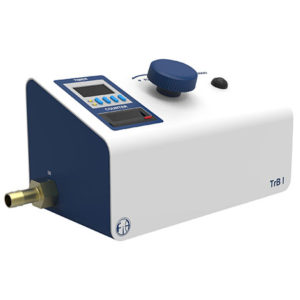

Trigger Box Model I – Basic

This model gives the analyst the basic functionality in a very compact and easily managed format.

Key features are:

- Flow actuation: 0-99 min, 0.1s resolution

- Actuation counter: Resettable, 8 digits

- Foot switch: Optional

- Display: 4 and 8 digits

- P1 Measurement: No

- P3/P2 Measurement: No

- Flow Measurement: No

- dP (e.g. stage dP): No

- Printable data: No

- Relay output for actuation of external equipment: No

- Displayed history of recent actuation data: No

- USB memory stick export: No

- Automatic leak test: No

- Dimensions (cm): 23x13x13

-

Training and IQ Metivent Software. Can be done remote via Skype or on-site. Request preference. The IQ results in a wet-ink protocol. The user gets a license to copyrighted text for e.g. internal maintenance work. Configurable for inhaler actuation. Configurable for camera sync. Configurable for load cell.

-

Threaded adapter (female) connecting NGI outlet to 25 mm (male) side of a ISO 22 mm standard filter. Recommended to be combined with this product with barbed fitting to connect to vacuum hose.

-

Holds 2 Syringes up to 60 mL each, can be different sizes.

Holds 2 Syringes up to 60 mL each, can be different sizes.

Infusion rates from 1.436 uL/hr (1 mL syringe) to 7515 mL/hr (60 mL syringe).

Easy-to-use keypad interface.

One-click program upload from "Pumping Program Generator" spreadsheet.

Space Saving Chassis: Foot print size of only 22.9 x 14.61 cm.

Won't take up unnecessary space on your laboratory or production bench.

Includes all the advanced functions and programming features of the NE-1000 series.

Disposable, Glass, Stainless Steel Syringes and Plumbing Supplies are sold separately. -

Same description and all the features of the DUAL-NE-1000 plus more.

Same description and all the features of the DUAL-NE-1000 plus more.

Includes: 2 NE-4000 two channel programmable syringe pumps, synchronization cable and two power supplies.

Holds 4 syringes up to 60 mL.

If you need to create two continuous infusion streams this requires 2 Dual Pump Plumbing Kits for full use of all four channels in the system. -

Does not have a built-in user interface.

Does not have a built-in user interface.

Chassis mountable: 24.1 x 10.2 x 10.5 cm.

If chassis does not fit in your system, we make custom designed OEM syringe pumps to accommodate your specific needs.

Operates from a 12V DC power source.

Holds 2 syringes, up to 60 mL each. 140 mL with long chassis.

Infusion rates from 1.430 uL/hr (1 mL syringe) to 7515 mL/hr (60 mL syringe).

Includes all the advanced functions and programming features of the NE-1000 family.

Disposable, Glass, Stainless Steel Syringes and Plumbing Supplies are sold separately. -

Holds 2, 4, 6, 8, 10 or 12 syringes of up to 3 mL each.

Holds 2, 4, 6, 8, 10 or 12 syringes of up to 3 mL each.

Infusion rates from 0.45 uL/hr (1 mL syringe) to 153.2 mL/hr (3 mL syringe).

Easy-to-use keypad interface.

Higher flow rate models available.

Includes all the Features of the NE-1000 Series of Syringe Pumps.

Includes all the advanced functions and programming features of the NE-1000 series.

Disposable, Glass, Stainless Steel Syringes and Plumbing Supplies are sold separately. -

Holds 2, 4, or 6 syringes of up to 140 mL each.

Holds 2, 4, or 6 syringes of up to 140 mL each.

Infusion rates from 0.452 uL/hr (1 mL syringe) to 1451 mL/hr (60 mL syringe).

Easy-to-use keypad interface.

One-click program upload from "Pumping Program Generator" spreadsheet.

Higher flow rate models available.

Includes all the advanced functions and programming features of the NE-1000 series.

Disposable, Glass, Stainless Steel Syringes and Plumbing Supplies are sold separately. -

All the features of the DUAL-NE-1000.

All the features of the DUAL-NE-1000.

Can approximately double the pressure of the DUAL-NE-1000 Two single syringe pumps, each pump holds 1 syringe up to 60 mL, or 140 mL partially filled.

Infusion rates from 0.73 uL/hr (1 mL syringe) to 2100 mL/hr (60 mL syringe).

Includes all the advanced functions and programming features of the NE-1000 family.

Disposable, Glass, Stainless Steel Syringes and Plumbing Supplies are sold separately.

Dual Pump Plumbing Kit, (sold separately), complete the continuous system.

Easy-to-use keypad interface.