-

Key features:

- Can be operated in a series

- Very accurate with a repeatability of 0.04% RSD

- Simplicity in design

- Long life time of dispensing equipment

- Constructed of glass and teflon

- Suitable for integration in robotic systems

- Can be ordered on a mobile platform for best working environment

- Full volume each stroke

- Impact time 10-20 sec

- No PLC nor computer dependent, but can be easily connected

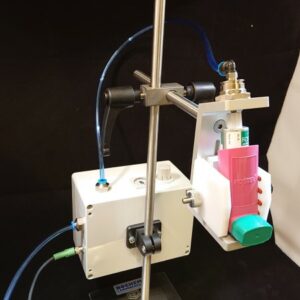

All dispensers require compressed air of 6-8 bar.

-

Key features:

- Can be operated in a series

- Very accurate with a repeatability of 0.04% RSD

- Simplicity in design

- Long life time of dispensing equipment

- Constructed of glass and teflon

- Suitable for integration in robotic systems

- Can be ordered on a mobile platform for best working environment

- Full volume each stroke

- Impact time 10-20 sec

- No PLC nor computer dependent, but can be easily connected

All dispensers require compressed air of 6-8 bar.

-

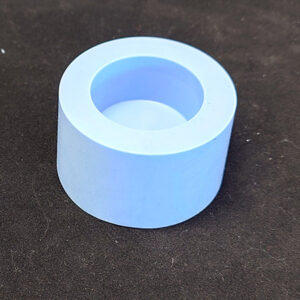

We have broad and long experience of reparing impactors, predominantly the NGI. Examples are:

- Nickel coating of NGI body and pre-separator

- TiN layer on USP induction port and pre-separator tapered male ends

- Polish severely scratched surfaces, such as joints between impactor parts (the NGI stage 1 female entry port is vulnerable) and surfaces around the entry of the induction port. Any measures are discussed with the customers prior, since some parts simply have reached end-of-life.

- Reconditioning nozzles on stages where the holes regain their original specifications, or repairing complete stages. Which are verified by optical or mechanical inspections, or through method for determining stage pressure drop:Impactor Nozzle Diameter Measurement NGI